At Sentinel Blast and Paint, we’re committed to helping our clients achieve their desired outcomes. This is why we employ a team of experienced and detail-orientated workers who have the necessary skills to deliver the required results. We also utilise an extensive range of equipment, allowing us to achieve a professional finish that is fully compliant with ISO Accredited specifications.

Located in Emerald, our facilities have been designed with the latest painting and blast technology in mind, while also considering the needs of our clients. The facility itself includes designated booths for blasting and painting, ensuring full-weather protection and a faster turnaround time.

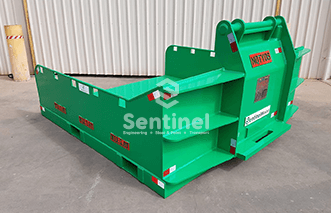

Sentinel offers a quality blast and paint and a selection of specialised abrasive blast and paint services suitable for a range of plant and heavy equipment in the mining, construction, agricultural, and transport industries.

We understand it’s not always possible or practical for business owners to transport their equipment off-site. This is why we offer onsite services throughout Central Queensland. Additionally, we can arrange for machinery to be retrieved directly from your worksite thanks to our Australia-wide transport options. This allows us to collect plant or machinery, transport it to our blast and paint facility in Emerald and then return it to your site once works are complete. Our in-house transport division ensures there are no third-party delays, meaning you can expect a faster turnaround time.

At Sentinel, we feel that together, we can raise industry standards to optimise equipment performance and reduce overhaul and maintenance costs.

We believe that this can be accomplished whilst consistently maintaining the highest levels of safety and quality control.

We would like to thank you for your time and look forward to discussing your project needs in more details.